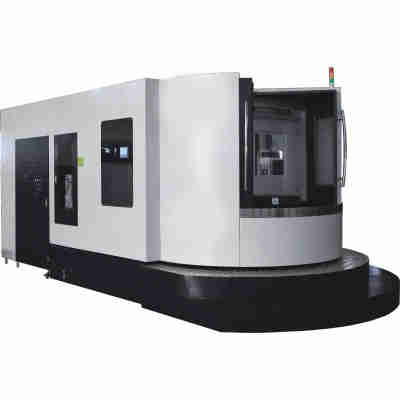

This series of column beam fixed double column machining centers adopts the international dynamic stiffness design concept to optimize the design of moving components based on the high stiffness, structural symmetry, and high stability of traditional double column machining. This series of machine tools has the characteristics of high torque and fast feedback, which can meet the needs of mechanical processing fields such as automobiles, molds, aviation, and industry. This series of machine tools mainly consists of components such as base, workbench, column, crossbeam, saddle, hydraulic system, lubrication system, cooling and filtering system, chip cutting device, CNC system, etc.The SP2240 double column machining center is a versatile and high-performance machine tool that offers several advantages for various applications. This machining center is designed to handle large and heavy workpieces with precision and efficiency.

One of the key advantages of the SP2240 double column machining center is its robust and stable structure. The double column design provides excellent rigidity and minimizes vibration during machining operations, ensuring high accuracy and surface finish. This makes it ideal for demanding applications that require precision, such as aerospace, automotive, and mold making industries.

The SP2240 machining center also offers a large working envelope, allowing for the machining of sizable components. With its spacious worktable and extended X-axis travel, it provides ample space for accommodating large workpieces, making it suitable for jobs that involve machining large molds, dies, or structural components.

Furthermore, the SP2240 is equipped with advanced CNC controls and spindle technology, enabling high-speed machining and multi-axis operations. It supports a range of machining processes, including milling, drilling, tapping, and contouring, providing versatility and flexibility in manufacturing complex parts.

- Home

- About Us

- Products

- Motors

- Sprockets

- Chains

- Pulley

- Gearboxes

- Screw Jacks

- PTO shafts

- Hydraulic Cylinder

- Gear

- Gear & Racks

- Coupling

- Wheel Hub

- Axles

- Air Compressor

- Vacuum Pump

- Agricultural parts

- Machining Lathe

- Sensor

- Other

- BN gearbox

- Agricultural Gearboxes

- Sprocket and chain

- Universal Joint

- trailer

- Taper Bushes

- Speed variator

- shaft collars

- Ungrouped

- Agricultural Equipment

- Rotary Cutter Gearbox

- Fertilizer Spreader Gearbox

- Rotary Tiller Gearbox

- Flail Mower Gearbox

- Rotary Mower Gearbox

- Disc Mower Gearbox

- Post Hole Digger Gearbox

- Feed Mixer Gearbox

- Round Baler Gearboxes

- Square Baler Gearboxes

- Hydraulic Drive Gearbox

- Rotary Rake Gearboxes

- Center Pivot Irrigation Gearboxes

- Orchard Sprayer Gearbox

- Potato Harvester Gearbox

- Silage Machine Gearboxes

- Corn Header Gearboxes

- Combine Harvester Gearbox

- Grain Storage Gearbox

- Grain Transportation Gearbox

- News

- Download

- Send Inquiry

- Contact Us