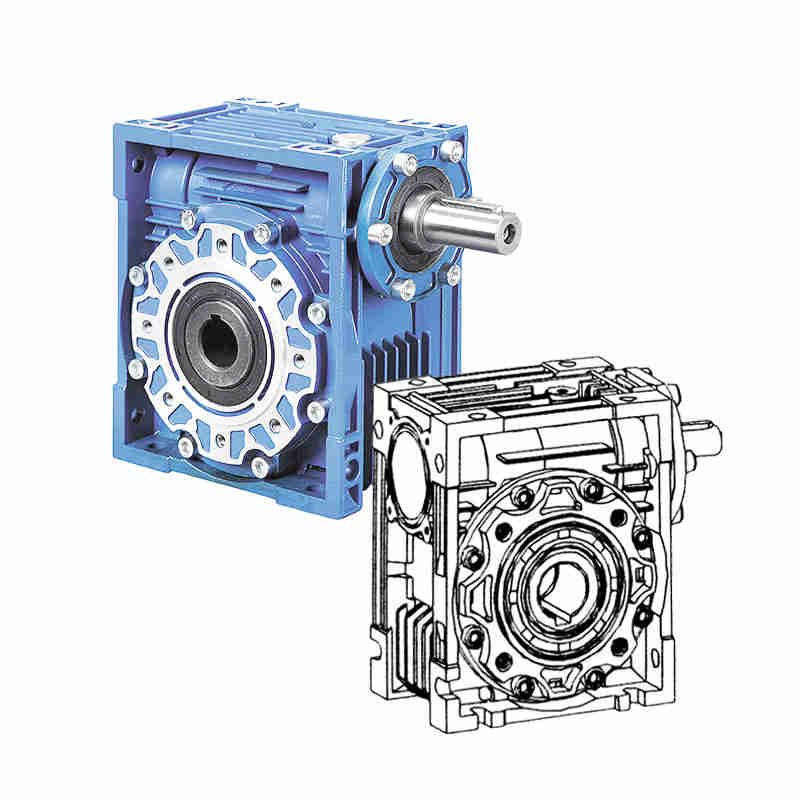

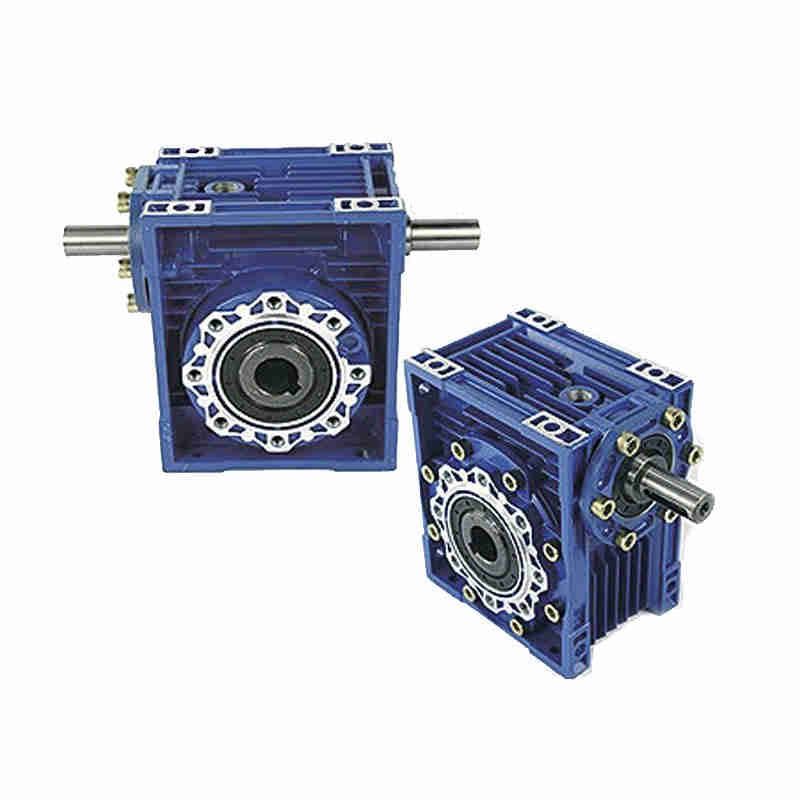

What is a Gear Motor?

A Gear motor is a specialized electromechanical device that integrates an electric motor with a gearbox (gearbox) to provide high torque at low speeds. This combination is essential in applications where motors alone cannot deliver sufficient force or require speed reduction. Gear motors are widely used across industries such as robotics, automotive, manufacturing, and consumer electronics due to their efficiency, reliability, and versatility.

The primary function of a gear motor is to multiply torque while reducing rotational speed. This is achieved through the gearbox, which contains a series of gears that transmit power from the motor to the output shaft. The gear ratio—defined as the ratio of input speed to output speed—determines the torque multiplication and speed reduction. For instance, a higher gear ratio results in greater torque but lower output speed.

Gear motors come in various types, including AC gear motors, DC gear motors, brushless gear motors, and planetary gear motors, each suited for specific applications based on factors like power requirements, environment, and cost. They are designed to operate in diverse conditions, from high-temperature industrial settings to precise medical equipment, offering customizable solutions for engineers and designers.

Key Parameters of Gear Motors

Understanding the technical specifications of gear motors is crucial for selecting the right product for your needs. Below are the essential parameters detailed in lists and tables for clarity.

Basic Parameters

- Rated Voltage: The operating voltage range (e.g., 12V DC, 24V DC, 110V AC, 220V AC) that the motor is designed for. Deviating from this range can affect performance and lifespan.

- Output Speed: Measured in revolutions per minute (RPM), this indicates the rotational speed at the output shaft after gear reduction. Typical ranges are from 1 RPM to 500 RPM, depending on the gear ratio.

- Output Torque: The twisting force delivered by the output shaft, measured in Newton-meters (Nm) or inch-pounds (in-lbs). Higher torque is essential for heavy-load applications.

- Gear Ratio: The ratio of input speed to output speed (e.g., 10:1, 50:1). A higher ratio means more torque but lower speed.

- Efficiency: The percentage of input power converted to mechanical output, typically ranging from 70% to 95% for quality gear motors.

- Operating Temperature: The range of ambient temperatures (e.g., -20°C to 80°C) within which the gear motor can function reliably.

- Protection Rating: Often denoted by IP (Ingress Protection) ratings (e.g., IP54, IP65), which indicate resistance to dust and water.

Detailed Specifications Table

| Parameter |

Description |

Typical Values |

Importance |

| Rated Power |

Power input the motor can handle continuously |

10W to 750W |

Determines load capacity and energy consumption |

| No-load Speed |

Speed at output shaft with no load applied |

5 RPM to 1000 RPM |

Indicates base performance without resistance |

| Rated Torque |

Torque delivered under rated load |

0.1 Nm to 500 Nm |

Critical for applications requiring force, like lifting |

| Gear Type |

Type of gears used (e.g., spur, planetary, worm) |

Planetary (high precision), Worm (self-locking) |

Affects efficiency, noise, and application suitability |

| Shaft Diameter |

Diameter of the output shaft |

6mm to 40mm |

Must match with driven components for compatibility |

| Weight |

Mass of the gear motor unit |

0.5 kg to 20 kg |

Important for portability and installation constraints |

| Noise Level |

Sound produced during operation |

<45 dB to <75 dB |

Key for consumer and medical applications where quiet operation is needed |

Applications of Gear Motors

Gear motors are integral to numerous industries due to their ability to provide controlled motion. Common applications include:

- Robotics: Used in robotic arms and mobile robots for precise movement and high torque.

- Automotive: Power window systems, seat adjusters, and windshield wipers rely on gear motors for smooth operation.

- Industrial Machinery: Conveyor belts, packaging equipment, and CNC machines use gear motors for consistent performance under load.

- Medical Devices: Hospital beds, infusion pumps, and surgical tools benefit from the reliability and precision of gear motors.

- Consumer Electronics: Appliances like washing machines, printers, and cameras incorporate gear motors for automated functions.

FAQs About Gear Motors

What is the difference between a gear motor and a regular motor?

A regular motor provides high speed but low torque, whereas a gear motor combines a motor with a gearbox to offer high torque at reduced speeds, making it suitable for applications requiring significant force.

How do I choose the right gear motor for my application?

Consider factors like required torque, speed, voltage, operating environment, and duty cycle. Calculate the load demands and match them with the motor's rated specifications, and consult datasheets or engineers for custom needs.

What maintenance does a gear motor require?

Maintenance typically involves periodic lubrication of gears, checking for wear and tear, and ensuring electrical connections are secure. Sealed units may require less maintenance, but always follow the manufacturer's guidelines.

Can gear motors be used in hazardous environments?

Yes, models with appropriate protection ratings (e.g., IP67 for dust and water resistance) or explosion-proof certifications can be used in hazardous conditions, but verify specifications for compliance with safety standards.

What is the typical lifespan of a gear motor?

Lifespan varies based on usage, load, and environment, but quality gear motors can last from 5,000 to 20,000 hours or more. Proper installation and maintenance extend longevity.

Are gear motors reversible?

Most DC and some AC gear motors are reversible by polarity switching, but check the product details as some designs (e.g., worm gear motors) may have self-locking features that prevent reversal.

How does gear ratio affect performance?

A higher gear ratio increases torque output but decreases speed, while a lower ratio does the opposite. Select a ratio based on whether your application prioritizes force or speed.

What are the common causes of gear motor failure?

Overloading, improper voltage, lack of lubrication, contamination, and excessive heat are common causes. Regular inspections and operating within specified limits can prevent failures.