What Is a Speed Variator?

A Speed variator is a mechanical or electromechanical device used to adjust and control the speed of machinery and equipment in various industrial applications. It allows for precise regulation of rotational speed, providing flexibility in operations where varying speeds are required for optimal performance. Speed variators are essential in industries such as manufacturing, automotive, and agriculture, where they help improve efficiency, reduce energy consumption, and extend the lifespan of machinery by enabling smooth acceleration and deceleration.

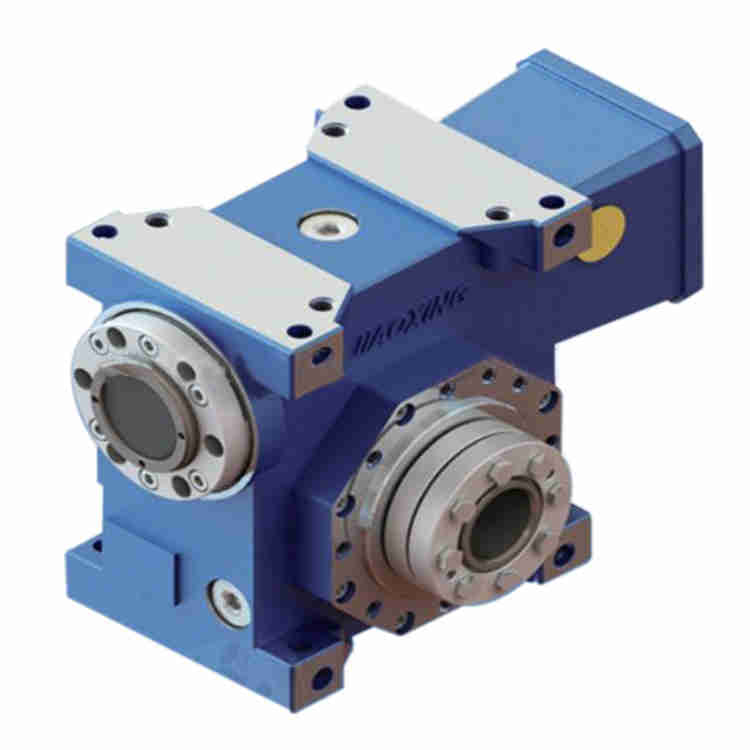

Key Components of a Speed Variator

- Input Shaft: Connects to the power source and transmits rotational energy into the variator.

- Output Shaft: Delivers the adjusted speed to the driven machinery.

- Control Mechanism: Allows users to manually or automatically adjust the speed ratio.

- Housing: Protects internal components from dust, moisture, and other environmental factors.

- Cooling System: Prevents overheating during prolonged operation, often through fins or fans.

Product Parameters and Specifications

Our speed variators are designed to meet high standards of durability and performance. Below is a detailed table of specifications for our flagship model, the SV-5000 series.

| Parameter |

Specification |

Units |

| Power Range |

0.5 - 10 |

kW |

| Speed Ratio |

1:1 to 1:5 |

Ratio |

| Input Speed |

Up to 3000 |

RPM |

| Output Speed |

100 - 1500 |

RPM |

| Efficiency |

92 - 95% |

Percentage |

| Operating Temperature |

-10 to 40 |

°C |

| Weight |

15 - 50 |

kg |

| Noise Level |

< 75 |

dB |

| Protection Rating |

IP55 |

Standard |

Applications of Speed Variators

- Conveyor Systems: Adjusting belt speed for different production lines.

- Pumps and Fans: Controlling flow rates to save energy and reduce wear.

- Machine Tools: Providing variable speeds for cutting, drilling, and milling operations.

- Agricultural Machinery: Adapting to varying terrain and load conditions in equipment like tractors.

- Food Processing: Regulating mixers and grinders for consistent product quality.

Advantages of Using Our Speed Variators

- Energy savings of up to 30% compared to fixed-speed systems.

- Precise control enhances product quality and reduces material waste.

- Durable construction with high-quality materials for long service life.

- Easy installation and maintenance, reducing downtime.

- Compatible with various motor types and industrial setups.

Frequently Asked Questions (FAQ)

What is the main function of a speed variator?

A speed variator primarily adjusts the rotational speed of machinery, allowing operators to control performance based on specific task requirements, such as varying loads or production speeds.

How does a speed variator differ from a gearbox?

While both devices manage speed and torque, a speed variator provides continuous and adjustable speed control without fixed gear ratios, offering more flexibility than a traditional gearbox which has predefined speed settings.

Can a speed variator be used with any motor?

Yes, most speed variators are designed to be compatible with standard AC and DC motors, but it's essential to check the manufacturer's specifications for power ratings and connection types to ensure proper matching.

What maintenance is required for a speed variator?

Regular maintenance includes lubricating moving parts, inspecting for wear, and ensuring the cooling system is functional. Typically, maintenance intervals are every 6-12 months, depending on usage intensity.

Are speed variators energy-efficient?

Absolutely. By allowing motors to run at optimal speeds rather than full power constantly, speed variators can significantly reduce energy consumption, leading to lower operating costs and environmental benefits.

What safety features are included?

Common safety features include overload protection, thermal shutoff to prevent overheating, and secure housing to protect against accidental contact with moving parts, complying with industry safety standards.

How do I choose the right speed variator for my application?

Consider factors such as the required power range, speed ratio, operating environment, and compatibility with existing machinery. Consulting with a technical expert or referring to product datasheets can help in selecting the appropriate model.

Can speed variators be automated?

Yes, many modern speed variators support automation through PLCs (Programmable Logic Controllers) or sensors, enabling integration into smart industrial systems for precise, hands-free control.

What is the typical lifespan of a speed variator?

With proper maintenance, a high-quality speed variator can last 10-15 years or more, though this depends on usage conditions, load factors, and environmental factors like temperature and humidity.

Do speed variators work in harsh environments?

Yes, models with higher protection ratings (e.g., IP55 or above) are designed to withstand dust, moisture, and extreme temperatures, making them suitable for demanding industrial settings.