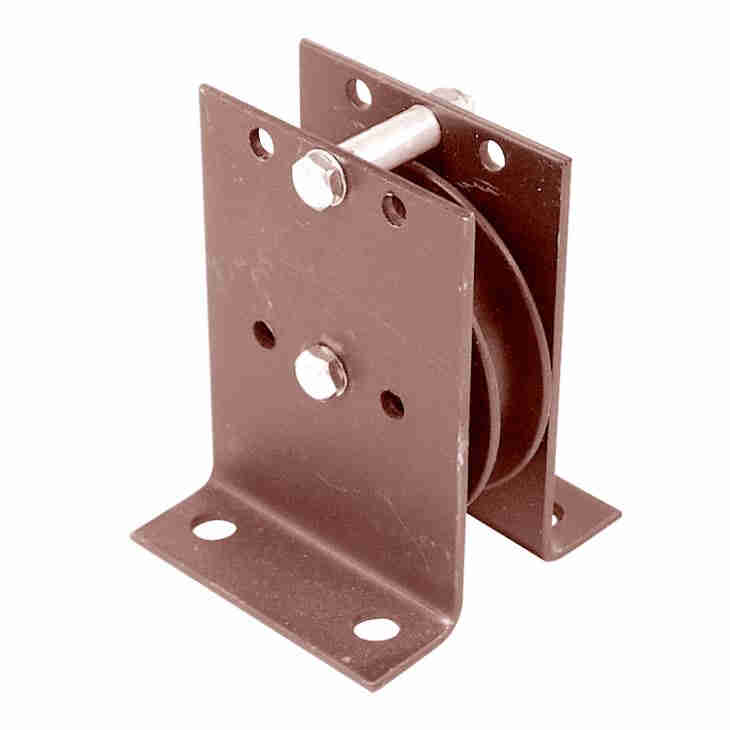

What is a Timing Pulley?

A Timing pulley is a specialized mechanical component used in power transmission systems to transfer rotational motion between shafts with high precision and minimal slippage. Unlike traditional pulleys, timing pulleys feature teeth that mesh with a belt, ensuring synchronous movement. This makes them ideal for applications requiring accurate positioning, such as in robotics, CNC machinery, and automotive systems. The design allows for efficient power transfer, reduced maintenance, and longevity in demanding environments.

Key Product Parameters

Our timing pulleys are engineered to meet rigorous industry standards, with precise specifications to ensure optimal performance. Below are the detailed parameters:

Material Specifications

- Aluminum Alloy: Lightweight, corrosion-resistant, and suitable for high-speed applications.

- Stainless Steel: Offers superior strength and durability for heavy-duty operations.

- Plastic (Nylon/POM): Cost-effective, quiet operation, ideal for light to medium loads.

Technical Dimensions

| Parameter |

Range |

Description |

| Bore Diameter |

5mm to 50mm |

Customizable to fit various shaft sizes with keyway or set screw options. |

| Number of Teeth |

10 to 120 teeth |

Determines the speed ratio and torque transmission capacity. |

| Pitch |

2mm to 14mm |

Standard pitches include MXL, XL, L, H, and T series for compatibility. |

| Outside Diameter |

20mm to 300mm |

Varies based on tooth count and pitch, affecting the overall size and application. |

| Width |

6mm to 40mm |

Designed to accommodate different belt widths for enhanced stability. |

Performance Metrics

- Max RPM: Up to 10,000 RPM, depending on material and design.

- Load Capacity: Ranges from 0.5 Nm to 200 Nm, tailored to application needs.

- Temperature Range: -40°C to 120°C for standard models; high-temperature variants available.

- Precision Class: ISO 13050 compliant with minimal backlash for accurate motion control.

Applications of Timing Pulleys

Timing pulleys are versatile components used across various industries due to their reliability and precision. Common applications include:

- Industrial Automation: In conveyor systems, packaging machines, and assembly lines for synchronized movement.

- Robotics: For precise joint control in robotic arms and actuators.

- Automotive: In engine timing systems, steering mechanisms, and transmission units.

- 3D Printers and CNC Machines: Ensuring accurate positioning of print heads and cutting tools.

- Medical Equipment: Used in devices like MRI machines and surgical robots for smooth operation.

Advantages of Our Timing Pulleys

Our products stand out due to superior engineering and quality assurance:

- High Precision: Manufactured with tight tolerances for minimal error in motion transmission.

- Durability: Made from robust materials to withstand wear, corrosion, and high loads.

- Customization: Available in various sizes, materials, and tooth profiles to meet specific requirements.

- Easy Installation: Designed with standard mounting features for quick integration into existing systems.

- Low Maintenance: Requires minimal upkeep due to efficient design and quality construction.

FAQs About Timing Pulleys

What is the primary function of a timing pulley?

The primary function is to transmit rotational power between shafts synchronously, ensuring precise positioning without slippage, which is critical in applications like automation and robotics.

How do I select the right timing pulley for my application?

Consider factors such as load capacity, speed (RPM), environmental conditions (e.g., temperature, exposure to chemicals), shaft size, and compatibility with the belt type (e.g., HTD, GT2). Our product tables and technical support can assist in selection.

What materials are best for high-temperature environments?

Stainless steel or specially coated aluminum pulleys are recommended for high-temperature applications, as they offer better heat resistance and durability compared to standard materials.

Can timing pulleys be used with any belt type?

No, timing pulleys must match the belt's tooth profile and pitch (e.g., MXL, XL, L) for proper meshing. Using mismatched components can lead to inefficiency, noise, and premature failure.

How often should timing pulleys be maintained or replaced?

Maintenance frequency depends on usage intensity and environment. Generally, inspect for wear, misalignment, or damage every 6-12 months. Replacement is needed if teeth are worn or there is significant backlash.

Are custom timing pulleys available?

Yes, we offer custom solutions including non-standard bore sizes, special materials, and unique tooth designs to meet specific operational requirements. Contact our team for details.

What causes timing pulley failure?

Common causes include improper alignment, overloading, using incompatible belts, lack of lubrication (in some designs), and environmental factors like contamination or extreme temperatures.

How do I install a timing pulley correctly?

Ensure the shaft is clean and free of debris. Align the pulley precisely with the shaft and secure it using the appropriate method (e.g., set screws, keyways). Check alignment with other components to avoid undue stress.