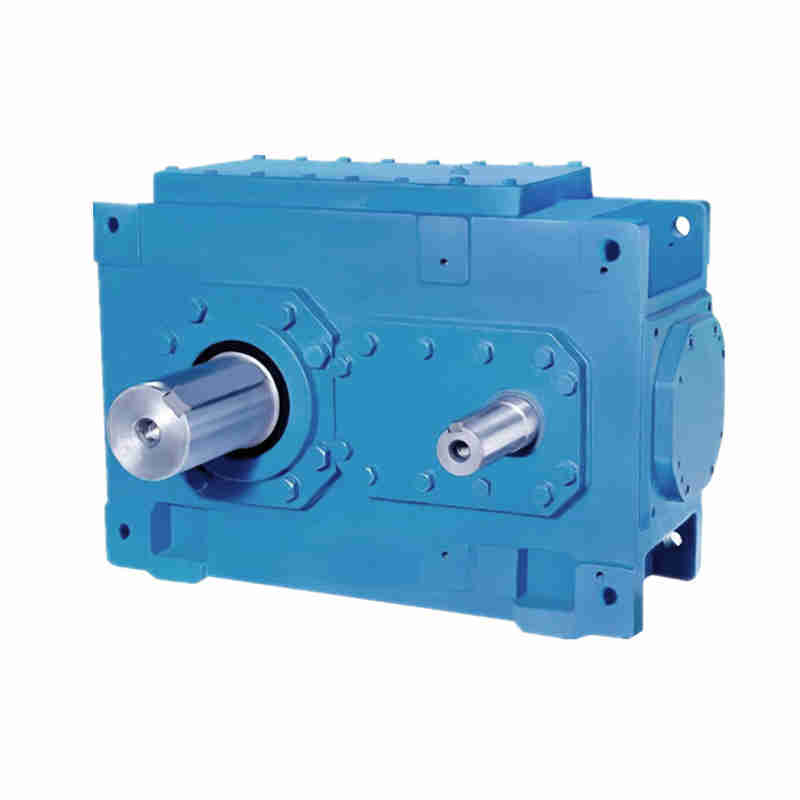

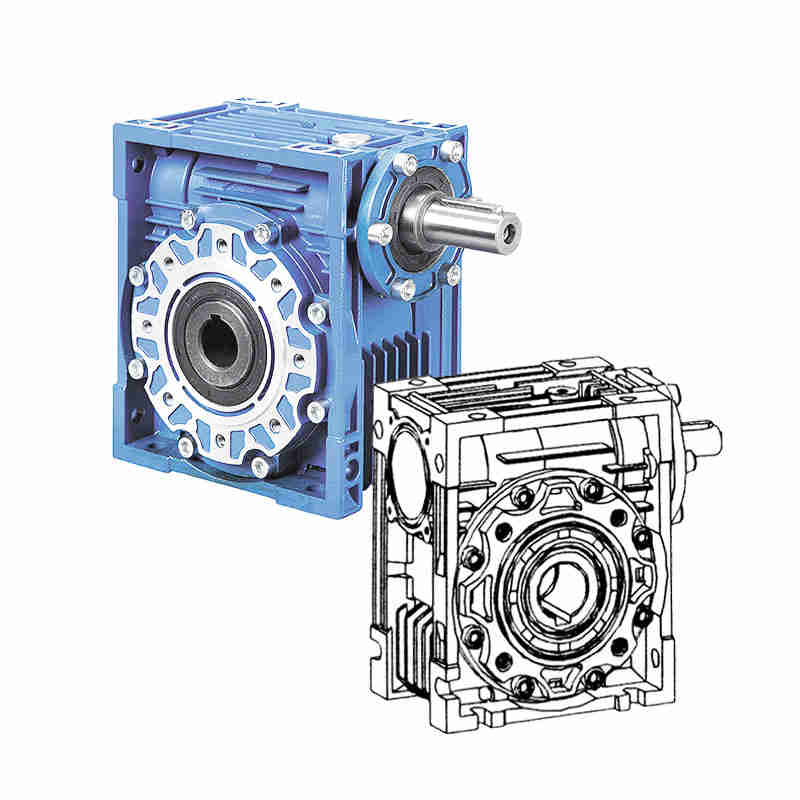

What Are Gearboxes?

A Gearboxes is a mechanical device used to transmit power and change the speed, torque, and direction of a mechanical system. They are essential components in various industries, including automotive, manufacturing, and energy, ensuring efficient operation of machinery by optimizing performance through gear ratios and design configurations.

Key Product Parameters

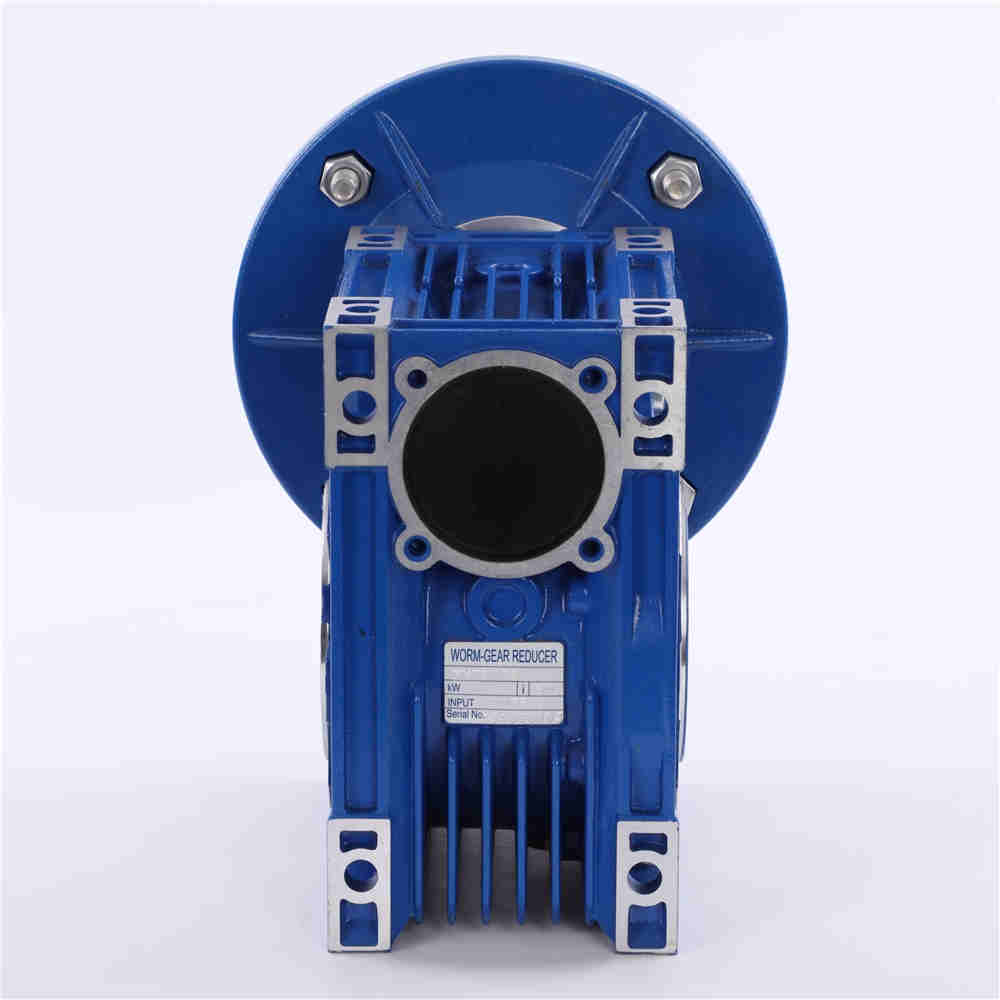

- Type: Helical, planetary, worm, bevel, and spur gearboxes, each suited for specific applications based on efficiency and load requirements.

- Gear Ratio: Ranges from 5:1 to 100:1 or higher, determining the output speed relative to input speed for precise control.

- Input Power: Typically from 0.1 kW to 500 kW, accommodating various motor sizes and operational demands.

- Torque Capacity: Up to 50,000 Nm, ensuring reliable performance under heavy loads and stressful conditions.

- Efficiency: Ranges from 85% to 98%, with higher efficiency in helical and planetary types reducing energy loss.

- Mounting Position: Options include foot-mounted, flange-mounted, or shaft-mounted designs for flexible installation.

- Material: Constructed from hardened steel, cast iron, or aluminum alloys, providing durability and corrosion resistance.

- Lubrication: Oil or grease lubrication systems, with maintenance intervals from 1,000 to 10,000 hours depending on usage.

- Noise Level: Below 70 dB for most models, ensuring quiet operation in noise-sensitive environments.

- Weight: Varies from 5 kg to 2,000 kg, based on size and material, impacting portability and structural support needs.

Detailed Specifications Table

| Model |

Gear Ratio Range |

Max Torque (Nm) |

Input Power (kW) |

Efficiency (%) |

Weight (kg) |

| Helical Standard |

5:1 - 20:1 |

10,000 |

0.1 - 100 |

95-98 |

10 - 500 |

| Planetary High-Torque |

10:1 - 100:1 |

50,000 |

5 - 500 |

90-97 |

50 - 2,000 |

| Worm Reduction |

10:1 - 60:1 |

5,000 |

0.5 - 50 |

85-90 |

5 - 300 |

| Bevel Angular |

5:1 - 30:1 |

15,000 |

1 - 200 |

92-96 |

20 - 800 |

Applications of Gearboxes

Gearboxes are used in diverse sectors such as automotive transmissions, industrial machinery, wind turbines, robotics, and conveyor systems. They enable precise motion control, enhance power transmission efficiency, and adapt to various operational environments, from high-speed applications to heavy-duty mining equipment.

Frequently Asked Questions (FAQ)

What is the typical lifespan of a gearbox?

The lifespan varies based on usage, maintenance, and type; with proper care, industrial gearboxes can last 10-20 years, while automotive ones may need replacement after 100,000 to 200,000 miles.

How do I choose the right gearbox for my application?

Consider factors like load requirements, speed ratios, environmental conditions (e.g., temperature and humidity), mounting options, and efficiency needs. Consulting technical specifications and manufacturer guidelines is recommended for optimal selection.

What maintenance is required for gearboxes?

Regular maintenance includes lubrication checks every 1,000-5,000 hours, inspection for wear and tear, alignment verification, and timely replacement of seals and bearings to prevent failures and extend service life.

Can gearboxes be customized for specific needs?

Yes, many manufacturers offer customizations in size, gear ratios, materials, and mounting configurations to meet unique operational requirements, though this may affect lead time and cost.

What are common signs of gearbox failure?

Indicators include unusual noises (e.g., grinding or whining), overheating, oil leaks, vibration, and decreased performance. Early detection through routine inspections can prevent major breakdowns.

How does gearbox efficiency impact energy consumption?

Higher efficiency gearboxes reduce energy loss through heat and friction, leading to lower operating costs and improved sustainability, especially in continuous-use applications like manufacturing plants.

Are there environmentally friendly gearbox options?

Yes, options include gearboxes made from recyclable materials, energy-efficient designs, and models compatible with biodegradable lubricants, supporting eco-friendly industrial practices.