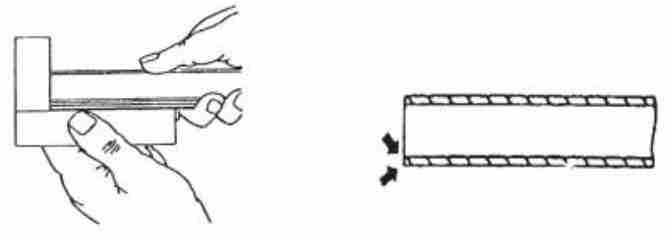

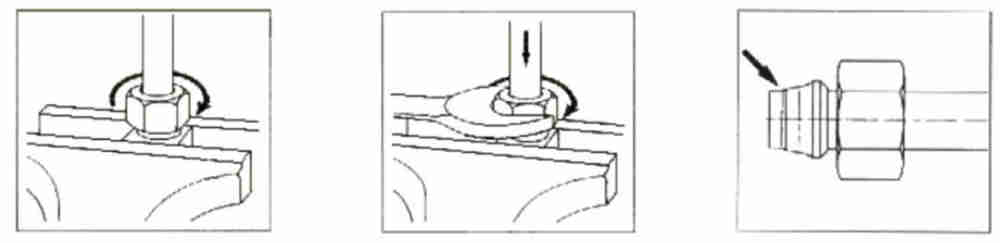

2. Lightly remove chips and particles from the inside and outside cut edges of tube. Bevel up to 0.2mm × 45 is permissible.

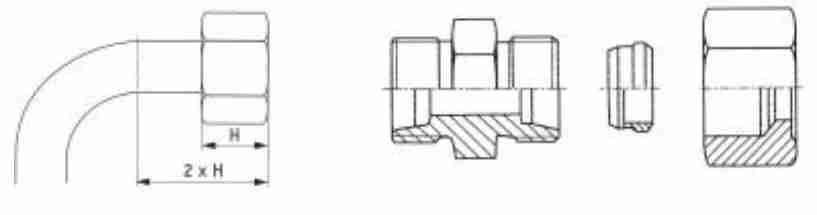

3. For tube bend, the minimum height from the straight pipe end to the bending radius must be at least twice the

height of the nut.

4. Lubricate thread and cone of the fitting body, ring and thread of nut.

- Home

- About Us

- Products

- Motors

- Sprockets

- Chains

- Pulley

- Gearboxes

- Screw Jacks

- PTO shafts

- Hydraulic Cylinder

- Gear

- Gear & Racks

- Coupling

- Wheel Hub

- Axles

- Air Compressor

- Vacuum Pump

- Agricultural parts

- Machining Lathe

- Sensor

- Other

- BN gearbox

- Agricultural Gearboxes

- Sprocket and chain

- Universal Joint

- trailer

- Taper Bushes

- Speed variator

- shaft collars

- Ungrouped

- Agricultural Equipment

- Rotary Cutter Gearbox

- Fertilizer Spreader Gearbox

- Rotary Tiller Gearbox

- Flail Mower Gearbox

- Rotary Mower Gearbox

- Disc Mower Gearbox

- Post Hole Digger Gearbox

- Feed Mixer Gearbox

- Round Baler Gearboxes

- Square Baler Gearboxes

- Hydraulic Drive Gearbox

- Rotary Rake Gearboxes

- Center Pivot Irrigation Gearboxes

- Orchard Sprayer Gearbox

- Potato Harvester Gearbox

- Silage Machine Gearboxes

- Corn Header Gearboxes

- Combine Harvester Gearbox

- Grain Storage Gearbox

- Grain Transportation Gearbox

- News

- Download

- Send Inquiry

- Contact Us