Common FAQs About Gearboxes

1. How to Choose the Right Gearbox for My Application?

Consider factors like load capacity, speed requirements, environmental conditions, and mounting style. Raydafon’s engineers can help assess your needs and recommend the best model—contact us for a free consultation.

2. Why Do Gearboxes Fail Prematurely?

Common causes include improper lubrication, overload, misalignment, or low-quality materials. Raydafon gearboxes are rigorously tested to avoid these issues, ensuring long-term reliability.

3. How to Maintain a Gearbox for Optimal Performance?

-

Regularly check oil levels and contamination

-

Monitor unusual noise/vibration

-

Follow the manufacturer’s service intervals

-

Use recommended lubricants (Raydafon provides maintenance guides)

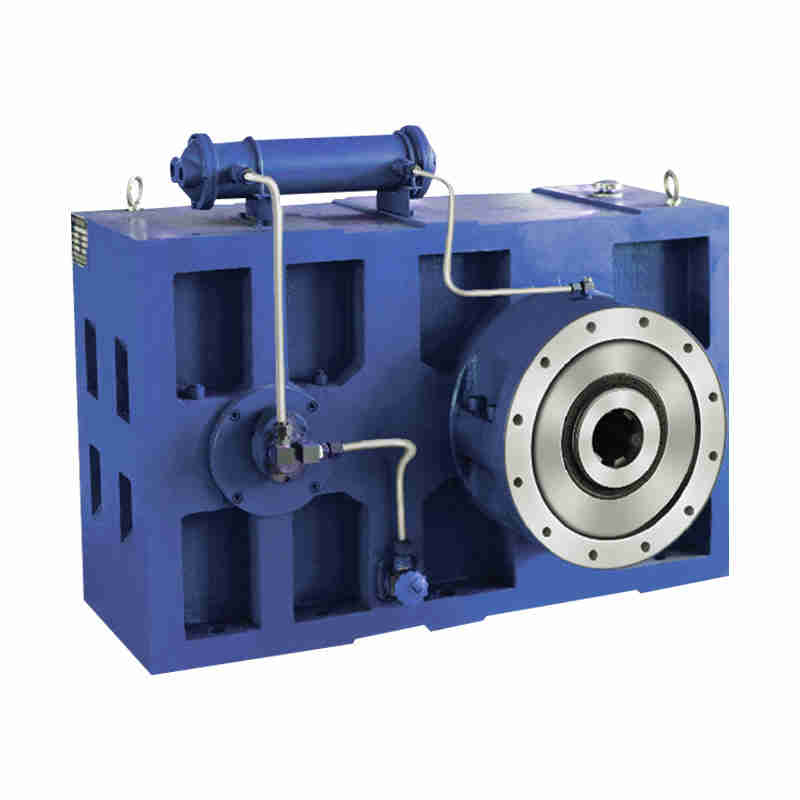

4. Can I Get a Customized Gearbox for Specialized Machinery?

Yes! Raydafon specializes in OEM/ODM gearbox solutions. Whether you need modified dimensions, unique gear ratios, or special coatings, our factory can develop a tailored gearbox for your exact needs.

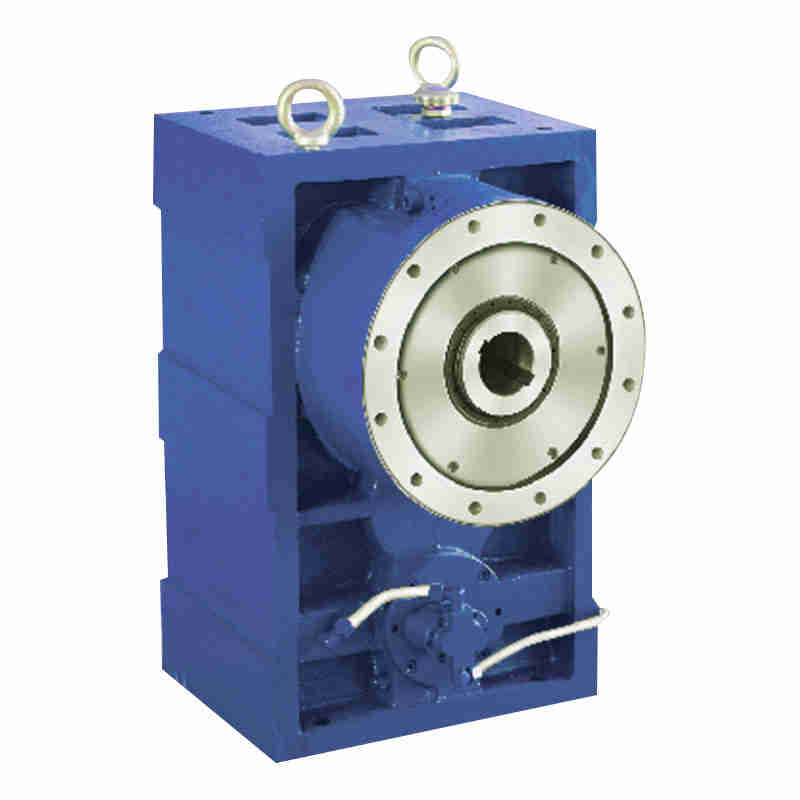

5. What Makes Raydafon Gearboxes Different from Other Suppliers?

We combine Chinese manufacturing efficiency with European-grade quality control. Our direct factory pricing eliminates middlemen, ensuring better value without compromising durability.

Request a Free Quote or Samples Today!

Ready to buy high-performance gearboxes from a trusted China manufacturer? Raydafon provides:

✅ Free technical support

✅ Competitive wholesale rates

✅ Custom OEM/ODM services

Contact us now to discuss your requirements or request a sample!